Pigments for Masterbatch & Plastics Applications

Date : 14-06-2019

Pigments are insoluble organic or inorganic particles added to the polymer base to give a certain colour to the plastic. The role of colorants and pigments in plastics these days involves much more than hues and shades. These additives now also are just as likely to affect factors such as processability, sustainability and compliance.

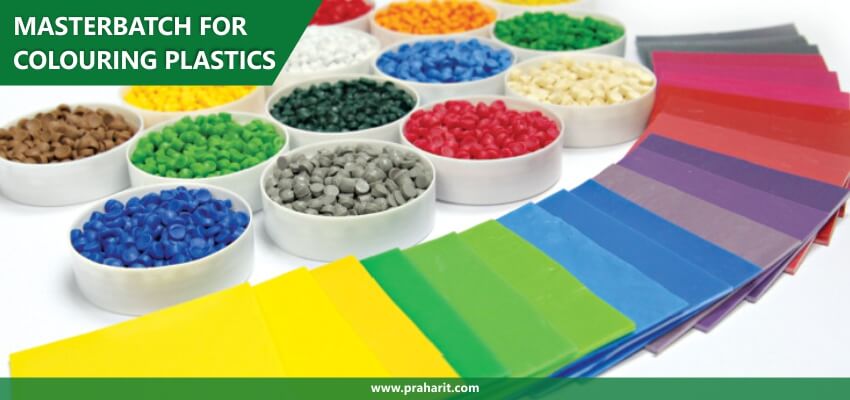

Masterbatch is a new kind of special colouring agent for polymer materials, also known as pigment preparation. It consists of three basic elements colour powder or dye, carrier and additive. Masterbatch is small granule shape used to add in plastics. It can dissolve and disperse in high temperature.

A Masterbatch is a concentrated mixture obtained by the distribution of colours and additives. The production of masterbatch creates great demands on the compounding process: The pigment and additive parts need to be merged into the base polymer completely homogeneously.

Properties of Performance Pigments for Plastic.

1. Weather / Aging

The main performance determined by Pigments for Plastic.

Effects of Sunlight on Plastic Products Sun exposure and some artificial lights can have adverse effects on the usefulness of plastic products. As a result, polymers used outdoors often require UV protection and weather resistant pigments.

The light stabilizing system must be considered together with the pigment formulation and the fastness criteria specified for the final product.

2. Light fastness

Light Fastness is a measure of the color fastness of plastic objects when used in indoor applications.

3. Warping & nucleation

The level of crystalline and the speed of crystallization determine the final properties of a plastic object. Organic pigments are known to affect these parameters during the plastic processing cooling phase, especially in HDPE injection molding.

4. Transparency

Transparency of Pigments Usually, transparency is obtained by reducing the size of pigment particles as much as possible.

This is achieved by surrounding particles as soon as they are formed with layers, which prevent crystal growth. This is very useful for printing ink pigments that are demanded to have high transparency and have the added advantage that such pigments are more easily dispersed.

Transparent variations are important because they are widely used for where high levels of transparency provide attractive results, and their weather resistance increases the resistance to pigments by which they can be combined.

Pigments Use in Following Types of Masterbatch:

White Masterbatch : White masterbatch has a various applications, lamination, coating, pipe, thermo-forming, protective film, fiber and non-woven, blow molding and injection molding. The advanced production capabilities contain high quality outdoor and indoor

Black Masterbatch : The Black Masterbatch range is based on polyethylene, polypropylene and universal carrier systems used in thin films, thick films, sheet extrusion, pipelines and irrigation, Roto Mold / Injection Mold / Blow Mold, Polyester staple fibers, fabrics & PET sheet.

Colour Masterbatch : Color masterbatches bring major changes in plastic resins and various applications such as industrial equipment for household appliances, textiles for packaging and designers, plastic processors relying on the latest color technology.

Additive Masterbatch : Additive masterbatches prevent deterioration & use in applications like packaging, consumer goods, automotive, building & construction, agricultural.

Special Effect Masterbatch : Use for well-finished plastic products & packaging design.

Praharit Pigments is a leading global Manufacturer of Organic pigments and dyes. Pigments by Application used in Fibers, Ink, coatings, textile, printing, plastics, consumer products and many more.

Praharit Pigments offers a complete range of Phthalocyanine pigments, organic pigments, dye preparations and optical brightness for the plastics industry. We specialize in supplying colours for all types of polymers in various market segments. Our products are specifically made for masterbatch manufacturers, compounders, polymer processors and polyvinylchloride, as well as manufacturers of resins and fibers. Recognized as a market leader in providing solutions to ecological and safety challenges, market with a broad and innovative palette of living components enhances our position as one of the leading providers for the benefit of our customers.

Praharit Pigments presents to masterbatch manufacturers, plastic processors and designers with a wide selection of support and service elements in the Product Safety field and regulatory environment. We offers one of the widest colour choices available from the entire colour spectrum.Â

At Praharit Pigments we ensure innovative solutions to meet your unique manufacturing needs. With over years of experience in Plastic industry, we offer a wide range of colorant pigments for following application

Our unmatched capabilities have made us an important supplier for various industries in a very short time. With continuous innovation in pigments, increased light fastness and resistance to various chemicals and solvents, we have achieved distinction from our various clients, a global presence with production facilities in the United States, Britain, Europe, Iran, China, Brazil as well as worldwide.